Alfa expanded clay is an efficient and lightweight aggregate with outstanding

fire resisting and insulation properties..

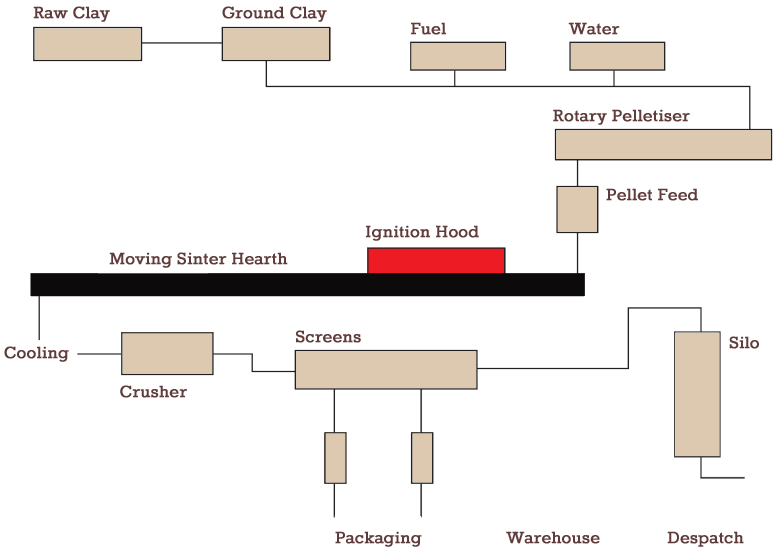

Three specific types of lightweight expanded clay aggregate are manufactured at our Kingsley factory in Staffordshire; EFG, REFAG and K25. A wide range of high quality clays are selected from around the United Kingdom, and from the Kingsley quarry. These clays are carefully mixed and blended to assure a consistent and stable chemical composition and then sintered on a moving hearth to form a porous ceramic sinter. Following a cooling period, the sinter is crushed and screened into fractions thus producing a range of grain sizes to suit customer requirements. All our refractory grade aggregates have low bulk density, high thermal insulation and refractoriness.

All grades are sold world-wide for a range of applications, which include:

Available in:

We export our materials extensively all over the world, and quotations can be readily provided to all destinations. Containers to deep-sea destinations are filled to capacity to minimise shipping costs. 40ft containers can be filled with IBC's or palletised sacks.

| K25 | EFG | EFG Low Iron | REFAG | |

| A2 2 O3 |

20-22% | 31-35% | 25-27% | 39-42% |

| Fe 2 O3 |

6.5-8.0% | 2.0-3.5% | 1.8-2.0% | 1.9-2.3% |

| Pyrometric Cone Equivalent | Cone 10 1300°C |

Cone 23-26 1610°C-1645°C |

Cone 17-18 1512°C-1522°C |

Cone 32-33 1717°C-1745°C |

| Loose Density Kg/M3 | 600-1050 | 625-1100 | 625-1100 | 630-1100 |

| Sizes Available | 10-5mm

5-2mm

5-0mm

2-0mm

Special grades available to customer requirements |

|||